2019.04

See here for several types of brick equipment for automated code cutting and transportation

Source: shandong miner myco

With the continuous development and progress of the society, automation technology has been widely used in various fields, dramatically changing the human ideology, work and life style, backward production technology and products will be eliminated.

For the brick making industry, many domestic manufacturers of brick production lines, equipment automation technology is still relatively backward, it is necessary to upgrade the equipment and technology of enterprises, so as to reduce the use of labor, to meet the requirements of energy conservation and environmental protection, in order to ensure the maximum economic benefits.

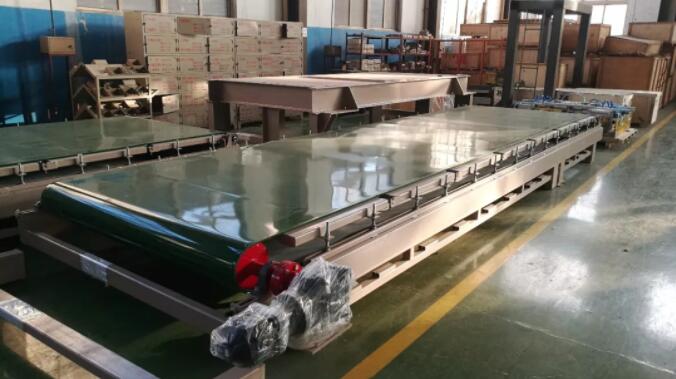

The automatic code cutting and transporting equipment produced by shandong mining machine maike building materials machinery co., LTD is mainly applied to the cutting, transporting, palletizing and unloading of new building materials factories and the transformation of automatic code putting production line of old brick factories limited by the site. All equipment can be automated, greatly reducing labor costs and improving production efficiency.

All kinds of equipment produced by the company have been served all over the country and exported to Bangladesh, Nepal, southeast Asia, Mongolia, Vietnam, Algeria, kazakhstan and other countries.

Billet gathering and moving machine (six rows)

Description of performance: according to the number of mud billets required by marshalling.

Equipment features: it has the function of processing waste billet and waste strip, as well as the function of temporary storage, effectively ensuring the continuity of production.

Briquetting machine (six rows)

Performance description: according to the requirements of process design for the way of brick-laying, the brick-laying is arranged.

Equipment features:

1. It is convenient to set whether the brick is flipped or not to achieve the smooth code of the brick;

2, according to the process design, can achieve a variety of brick type, different form of the code, intelligent split seam grouping;

3. The marshalling forms are flexible and diverse, different brick types can achieve one-key conversion, and the top push head of marshalling adopts servo control to realize unequal spacing of the bricks.

Billet loader

Performance description: it is mainly used to transport the marshalling bricks to the specified location to achieve longitudinal and transverse split.

Equipment features: compact structure, suitable for a variety of kiln, less energy consumption, cost savings. The equipment adopts advanced PLC control, servo motor, accurate positioning, high degree of automation.

Robot support

Performance description: straddling the kiln truck, supporting and fixing the billet manipulator.

Preform robot

Description of performance: put the bricks temporarily stored in the billet transport machine on the kiln car.

Equipment features: high positioning accuracy, in the link between the billet and the billet under the billet conveyor to achieve seamless docking. With collision stop function, flexible action, small space, can be added according to customer demand linear tracking function.

General jig

Performance description: by changing the splint of different thickness, the clamping of different brick types can be realized, so as to achieve the stacking requirements of different brick types.